Bob Ortblad shares the virtues of an immersed tunnel design over the current I-5 Bridge replacement project

Editor’s note: Opinions expressed in this letter to the editor are those of the author alone and may not reflect the editorial position of ClarkCountyToday.com

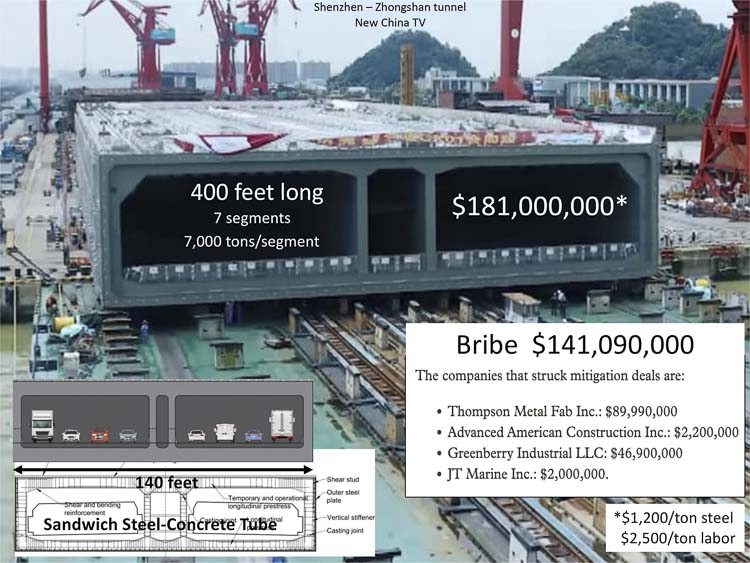

The Interstate Bridge Replacement Program (IBR) is bribing ($141 million) four upstream marine and metal fabrication firms for bridge clearance mitigation, reduced from 178 feet to 116 feet. Taxpayer money would be better spent on hiring these firms to fabricate seven 400-foot-long sandwich steel-concrete tubes for an immersed tunnel. Seven tubes could be fabricated for about $181 million and could span 2,800 feet across the Columbia River. Deduct IBR’s $141 bribe, and the net cost is $40 million.

The IBR’s “Tunnel Concept Assessment” (July 14, 2021), prepared by WSP engineers, fraudulently disqualified an immersed tunnel alternative. The report completely ignored a “Sandwich Steel-Concrete Immersed Tunnel” design alternative that can save hundreds of millions. Using existing shipyards, steel tubes can be fabricated by firms like Thompson Metal Fab, Greenberry Industrial, and Vigor Marine.

WSP engineers falsely claimed that the construction of a new casting basin costing hundreds of millions would be needed for the casting of concrete tunnel tubes. WSP also more than doubled the necessary cubic yards of excavation and dredging. WSP falsely claims a tunnel will be twice the cost of a bridge.

Public disclosure requests forced two revisions that cut the cubic yards estimate in half and added a professional engineer stamp that is required by law. The IBR never announced or circulated revised reports. Eight agencies approved IBR’s Modified Locally Preferred Alternative design based on the original incorrect report.

WSP is the IBR’s General Engineering Consultant (GEC) and has been paid over $90 million for poor design and management that has increased IBR’s consultant budget from $44 million to $295 million. WSP should be terminated.

Examples of Sandwich Steel-Concrete Immersed Tunnels:

- The Uminomori Tunnel in Tokyo Port was completed in 2020 using a steel-concrete sandwich design. It has four traffic lanes and was built with seven 440-foot tubes totaling 3,080.

- The Chinese Shenzhen – Zhongshan immersed tunnel was completed in 2024 using a steel-concrete sandwich design. It is nine miles long, with 32 tubes, and has eight traffic lanes.

A Nippon Steel report titled “Development of Sandwich-Structure Submerged Tunnel Tube Production Method” explains in detail the history of several Japanese immersed tunnels.

An I-5 immersed tunnel using a sandwich design with eight traffic lanes will need seven 400-foot tubes requiring about 50,000 tons of steel. These tubes can be fabricated by local companies with local labor for about $181 million. It will take a few $100 millions more to fill these tubes with concrete, transport them two miles, sink & connect in a dredged trench, connect to approaches, install ventilation and fire protection. The total cost of an immersed tunnel could be half the IBR’s $2,571,224,084 bridge.

The IBR estimates $2.8 billion for bridge approaches, $2.6 billion for a bridge, and $488 million to remove the current bridges. Building an immersed tunnel upstream of the current bridges and preserving the current bridges for local traffic and shared use path has the potential to cut a new I-5 crossing’s cost in half.

The IBR has also exaggerated the seismic risk of the current bridges.

Saving:

- No demolition of current bridges

- Preserve current approaches and bridges for local traffic & shared use path

- No drilled shafts (96) and temporary piles (1,775)

- No in river construction of bridge piers, columns, and truss spans

Bob Ortblad MSCE, MBA

Seattle

Also read:

- Opinion: A-pillars – The safety feature that increases crashesDoug Dahl explains how wider A-pillars designed to protect occupants in rollovers may also reduce visibility and increase crash risk for other road users.

- Opinion: Interstate Bridge replacement – the forever projectJoe Cortright argues the Interstate Bridge Replacement Project could bring tolling and traffic disruptions on I-5 through the mid-2040s.

- Opinion: Oversized tires and the frequency illusionDoug Dahl explains why tires that extend beyond fenders are illegal and how frequency illusion shapes perceptions about traffic safety.

- Opinion: IBR’s systematic disinformation campaign, its demiseNeighbors for a Better Crossing challenges IBR’s seismic claims and promotes a reuse-and-tunnel alternative they say would save billions at the I-5 crossing.

- Opinion: Is a state income tax coming, and the latest on the I-5 Bridge projectRep. John Ley shares a legislative update on a proposed state income tax, the I-5 Bridge project, the Brockmann Campus and House Bill 2605.